Polyethylene Glycols

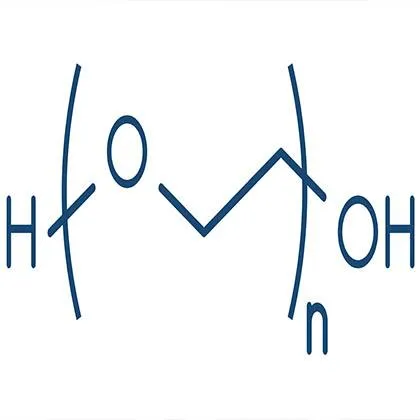

What is peg? Polyethylene glycol (PEG, CAS Number: 25322-68-3, peg full form) is chemically a polyether compound. Mostly it is formed by the addition of ethylene oxide to ethylene glycol or diethylene glycol. Therefore the common structure of Polyethylene glycol can be expressed as H−(O−CH2−CH2)n−OH. Polyethylene glycol structure forms a crystalline thermoplastic polyether that is practically water-soluble in applicable concentrations and exhibits very low immunogenicity, antigenicity and toxicity. Polyethylene glycol structure is a hydrophilic molecule, having high flexibility. The excellent aqueous solubility of Polyethylene glycol is due to the distance of the oxygens in the glycol structure that is similar with the distance of the hydrogens in the water molecule. This property is unique to Polyethylene glycols among all other aliphatic polyethers which are commonly not water-soluble.

Most Polyethylene glycol differ only in their molecular weights, hydroxyl numbers and viscosity profiles. Polyethylene glycol are named based on the number of units of ethylene glycol, or on their molecular weights. Low molecular weight Polyethylene glycol are in the liquid state, average molecular weight Polyethylene glycol appear as semisolids or waxy solids, while higher molecular Polyethylene glycol exist as waxy or crystalline solids in flake or powder form.

Fig. 1.1 - Polyethylene Glycol formula.

Poly(ethylene glycol) is the most biocompatible polymer having applications in fields like pharmaceuticals, medical for tablet film coating formulations, laxatives, food additives & cosmetics. In the cosmetic field, Polyethylene glycol are used widely in skin care products combined with glycerin. The application of Polyethylene glycol, which is important for skin creams, ointments, and suppositories, depends on the melting point of polyethylene glycol which depends on the chain length. The high molecular weight Polyethylene glycol have approximate melting point ~ 65 °C while lower molecular weight Polyethylene glycol are liquids. Polyethylene glycol can be custom-made in the physiological temperature range (36.1 - 37.2 °C) by blending different molecular weights. Polyethylene glycol is sold and marketed by several companies under well known trade names that are established for medical, cosmetic, and pharmaceutical purposes.Pharmaceutical formulations and cosmetics use Polyethylene glycol with smaller molecular weights. The lower the molecular weight, it helps the active compounds to penetrate the skin. In cosmetic application, Polyethylene glycol can function in three different ways: as emollients which helps to soften and lubricate the skin; as emulsifiers which help mix water- and oil-based ingredients thoroughly, and as delivery vehicles that help transport other ingredients deeper into the skin.

Polyethylene glycol (PEG) is the most widely used "stealth" polymer in the drug delivery field, due to its long history of safety in humans and classification as Generally Regarded as Safe (GRAS) by the FDA. US FDA's Inactive Ingredient Guide (IIG) (or Inactive Ingredient Database (IID)) lists the use of Polyethylene glycol and their maximum concentration in oral, topical, and intravenous formulations.In the medical field, PEGylating proteins allows to evade the immune system and thereby prolong circulation lifetimes and decrease immunogenicity (the ability of a foreign substance, to provoke an immune response in the human body). Similarly, coating the surface of nanoparticles with Polyethylene glycol (PEG), or "PEGylation", is a commonly used approach for improving the efficiency of drug and gene delivery to target cells and tissues. The FDA approved the first PEGylated nanoparticle (NP) product, Doxil®, in 1995. These Doxil "Stealth®" liposomes increased doxorubicin (anticancer drug) bioavailability nearly 90-fold at 1 week from injection versus free drug, with a drug half-life of 72 h and circulation half-life of 36 h. It has been demonstrated that PEG MW of 2 kDa or higher is required to shield NP surfaces from protein adsorption and reduce recognition by the mononuclear phagocyte system (MPS).The main ingredient in anti-freeze formulation is Polyethylene glycol.

Polyethylene glycol are used in drug delivery systems because they are neutral, nontoxic, and water soluble and can form micelles which are biocompatible and biodegradable.Polyethylene glycol are useful in detergent formulations as antideposition agents. Polyethylene glycol is a highly effective anti-redeposition agent on both polyester fabrics, synthetic-cellulose garments and polyester-cotton fabrics. Secondly, Polyethylene glycol are used as binder in powder formulations to effectively ensure that all the components are held together as granules. The choice of high or low melting Polyethylene glycol to be added in the formulation is usually done based on the ambient temperature where the powder detergent product will be distributed or sold. Apart from the above mentioned application or uses of glycol, based on their non-toxic nature, Polyethylene glycol also are non-corrosive. Therefore, they can be comfortably used in contact with materials like, rubber, plastic, metals, textiles without causing damage or staining. PEGs do not support microbial growth (resistance to mould growth) and rancidity hence an ideal excipient for liquid dosage forms.

Polyethylene Glycol 200

Polyethylene glycol 200 (PEG 200, CAS Number: 25322-68-3) is a colorless, non-volatile, hygroscopic liquid. It is soluble in water, and organic solvents like acetone, alcohol, benzene, and other glycols. Due to it low molecular weight and properties Polyethylene glycol-200 has a wide range of potential uses. Polyethylene glycol 200 is used as a defoaming agent, lubricant and viscosity modifier in many different products. Polyethylene glycol-200 is used as a coating for fresh fruit to preserve their freshness, as a solvent in metal working fluids, heat transfer fluids, as a binder and modifier in latex paints, and as a humectant in inks and abrasives. Polyethylene glycol 200 also finds use in formulations of resins, adhesives, as antistatic agent, in chemical intermediates, release agent and plasticizers. Specific industries like agriculture, cosmetics, detergents, health and medicine, textiles also rely on Polyethylene glycol-200 for its emulsifying and non-corrosive property.

Polyethylene Glycol 400

Polyethylene glycol 400 (PEG 400, CAS Number: 25322-68-3) is a low-molecular-weight grade of Polyethylene glycol. It is a clear, colorless, viscous liquid. Polyethylene glycol-8 is also known as Polyethylene glycol 400, where 400 represents the average molecular weight of the compound. Due in part to its low toxicity, Polyethylene glycol 400 is widely used in a variety of pharmaceutical formulations. For example Polyethylene glycol 400 help dissolve a large number of substances that do not readily dissolve in water by forming complexes with active substances. Therefore Polyethylene glycol 400 functions as solubilising agents for these active substances and excipients in liquid and semi-solid preparations. Polyethylene glycol 400 functions as viscosity modifiers and stabilizers for liquid pharmaceutical preparations and ointments. Polyethylene glycol 400 is also used as a inactive ingredient in intravenous injections. Polyethylene glycol 400 is soluble in water, acetone, alcohols, benzene, glycerin, glycols, and aromatic hydrocarbons, and is slightly soluble in aliphatic hydrocarbons. The low-molecular-weight formulations of Polyethylene glycol (e.g. PEG 400), find use in HP design jet printers as a solvent for ink and lubricant for the print heads.

Polyethylene Glycol 600

Polyethylene glycol 600 (PEG 600, CAS Number: 25322-68-3) is a medium-molecular-weight grade of Polyethylene glycol.

Polyethylene glycol 600 exist as clear colorless liquid with approx. mol weight of 630-670. It can be used in formulation for adhesives, as antistatic agent and humectant. Polyethylene glycol 600 can be utilized for chemical intermediates like PEGlyation in the medical field for its reported "stealth" properties and biocompatibility. It is generally thought that PEGylation allows particulate delivery systems and biomaterials to evade the immune system and thereby prolong circulation lifetimes. Polyethylene glycol 600 is also used in formulation of inks, lubricants and as a mold release agent.

Polyethylene Glycol 1500

Polyethylene glycol 1500 (PEG 1500, CAS Number: 25322-68-3) with a hydroxyl number of 70-85 mg KOH/g typically exists as white to off white flaky solid with approx. mol weight of 1300-1600. The solubility of a 5% solution is clear and colourless, and hence find use in cosmetic and drug delivery applications.

Polyethylene Glycol 3350

Polyethylene glycol 3350 (PEG 3350, CAS Number: 25322-68-3) is used to treat occasional constipation. Polyethylene glycol 3350 is in a class of medications called osmotic laxatives. It works by causing water to be retained with the stool. This increases the number of bowel movements and softens the stool so it is easier to pass. Polyethylene glycol 3350 is a laxative solution that increases the amount of water in the intestinal tract to stimulate bowel movements. Polyethylene glycol 3350 is a constipation powder used as a laxative to treat occasional constipation or irregular bowel movements. Venus Ethoxyethers subsidiary Avesta Pharma manufactures Polyethylene glycol/Macrogol 3350 for supply to US, Europe and Canadian markets. Polyethyele glycol 3350 powder for oral solution is commercially branded as Pegred powder, muout syrup, MiraLax, peg fiber, pegmove powder, laxopeg sachet

Polyethylene Glycol 4000

Polyethylene glycol 4000 (PEG 4000, CAS Number: 25322-68-3, commonly refered to as Polyethylene glycol 4000) typically exists as white to off white flaky solid with a hydroxyl number of 28-36 mg KOH/g and approx. mol weight of 3100-4010. The solubility of a 5% solution is clear and colourless. These Polyethylene glycol polymers are used in a wide variety of products including bath products, shaving products, skin care products, makeup, skin cleansing products, shampoo, hair conditioners and deodorants. Venus Ethoxyethers manufactures technical grade while its subsidiary Avesta Pharma manufactures Polyethylene glycol/Macrogol 4000 for supply to European markets. As per the IID, Polyethylene glycol 4000 is used in pharmaceuticals as tablet film coating component, mainly via the oral administration route.

Polyethylene Glycol 6000

Polyethylene glycol 6000 (CAS No. 25322-68-3) is a derivative of Polyethylene glycol having white to off white color and available in solid flakes or powder form. The melting range for Polyethylene glycol 6000 is between 58-63 oC and the average molecular weight can be within 5000-7000. Due to its lamellar structure, it may find use in pharmaceutical production of pills and tablets as binder or dry lubricant. Polyethylene glycol-6000 also finds use in enbalming of histological and other medical specimens when dissolved in lower glycols in place of paraffin wax. In cosmetics, Polyethylene glycol 6000 due to its binding property finds use in facial makeup and as wetting agents to inhibit soap cracking. The non-ionic property of Polyethylene glycol 6000 can facilitate the even distribution of electrolytes in galvanic baths for copper & nickel electroplating of steel and iron parts when added as a component. It can also function as anti-dusting agent for after-bath talcum powder, lubricant in paper industry, as a tyre mounting agent, as an additive in grease , as plasticiser in synthetic resin , as enhancer of thermal stability in adhesive preparations. In the rubber industry Polyethylene glycol 6000 at loading of 3-20% may function as mold release agent.

Polyethylene Glycol 8000

Polyethylene glycol 8000 (CAS No. 25322-68-3) is a Polyethylene glycol having white to off white color and available in solid flakes or powder form. Its high molecular weight mainly prompts its use in pharmaceutical formulations as solvent for oral, topical and parenteral preparations. Polyethylene glycol 8000 is used in pharmaceuticals as film coating component, for tablets with multilayer or extended release functions mainly via the oral administration route. The high molecular weight Polyethylene glycol 8000 is soluble in water and organic solvents such as alcohols. It can blend with other Polyethylene glycol molecular weights to achieve the desired viscosity properties. Polyethylene glycol 8000 is quite stable and does not support microbial growth, even in aqueous solutions.

Polyethylene Glycol 12000

Polyethylene glycol 12000 (PEG 12000, CAS Number: 25322-68-3) is a colourless polymer of ethylene oxide with an average molecular weight of 12000. This flaky material melting between 57-64oC is highly water soluble and functions as excellent solubilizers. Like most other Polyethylene glycol it is soluble in organic solvents, water and aromatic hydrocarbons and has limited solubility in aliphatic hydrocarbons. Therefore it can be used in a wide variety of home care applications like dish wash, fabric and laundry detergents, hard surface cleaning, in waxes and polishes and large scale industrial & institutional applications. Apart from these applications Polyethylene glycol 12000 also functions as a dispersant, in toothpastes, is used to modify therapeutic proteins and peptides to increase their solubility and prevent immunogenecity. In analytical applications like gas chromatography, it can function as a polar stationary phase. It is also useful in preserving objects obtained from the ocean. It finds application in blood banking as a potentiator, which is used to detect antigens and antibodies.

Polyethylene Glycol 20000

Polyethylene glycol 20000 S (CAS No. 25322-68-3) is a solid Polyethylene glycol with a mean molecular weight of 20000 available in flake form. The high molecular weight provides several benefits like excellent solubility in water, low moisture content, highly compatible with hard water, non-volatile non-toxic and generally safe. It belongs to non-hazardous substance or mixture according to Regulation (EC) No. 1272/2008 of the European Union. Considering the safety profiles, studies with drugs like simvastatin for improving their solubility were tested with Polyethylene glycol 6000, 12000 and 20000. These studies indicated higher phase solubility of drug and could influence the drug dissolution rate from such dispersion mixtures.

Related Products & Pages & Pages

Products with Related CAS Numbers

Frequently Asked Questions

Find answers to common questions about our products and services

No FAQs found

Try adjusting your search terms